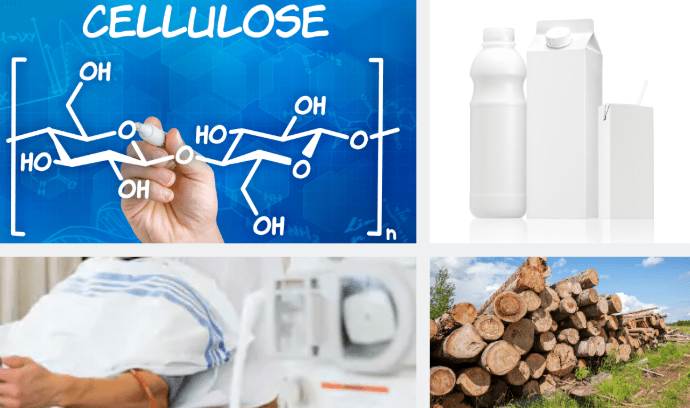

New plant-based material could impact healthcare, food, and timber industries

February 07, 2019The food packaging industry is in pursuit of clear, edible moisture barriers because they could address problems that are currently unsolvable. Such a material would decrease food spoilage, maintain freshness, be sustainable, and ingestible by humans. A collaborative team of researchers at the University of Arkansas in Fayetteville and the University of Arkansas for Medical Sciences has developed a new material that could do just that.

Dr. Jamie Hestekin, a membrane scientist from the Chemical Engineering department at UAF worked with Dr. Peter Crooks, a pharmaceutical scientist from the College of Pharmacy at UAMS to develop a material that demonstrates desirable properties in early testing, possibly opening up a multi-billion dollar market. Together with Dr. Hestekin’s graduate student John Moore, and postdoctoral fellow Dr. Soma Shekar Dachavaram, they filed a patent on this new form of incredibly hydrophilic cellulose.

Cellulose is a compound found in plants that keeps the cell walls rigid. It is not digestible, but can be used as dietary fiber and in other applications like cloth and paper. Cellulose is also a byproduct of the forestry industry, historically being used for paper. Research is being done worldwide on finding other applications of cellulose that are of value.

The new material is unique due to its complex nanoscale structure. For reference, a nanometer is somewhere between a strand of DNA and a single atom. Imagine taking one human hair and splitting it lengthwise into 80,000 pieces. The researchers found a way to assemble the cellulose into nanorods and nanoparticles that are less than 10 nanometers in length.

The material also shows promise in hemodialysis applications. During hemodialysis, blood is passed through a filter outside the body like an artificial kidney. Current filters could be improved by allowing better flow-through and less fouling. Testing shows that the cellulose material allows more blood to flow through a specific area in less time, and shorter fouling times.

Private companies have approached the team; they are also exploring it as an edible moisture barrier via dip coating and spray coating methods. The material is biocompatible, biodegradable, and can be produced sustainably. It will likely be a few years before the general public would encounter a product made from this new material, but it is very promising.

This development was supported by the Center for Advanced Surface Engineering, NSF RII Track-1 Award OIA-1457888. For more information on the Center for Advanced Surface Engineering and Arkansas NSF EPSCoR, please visit arepscor.org.

![]()

Dr. Jamie Hestekin, a membrane scientist from the Chemical Engineering department at UAF worked with Dr. Peter Crooks, a pharmaceutical scientist from the College of Pharmacy at UAMS to develop a material that demonstrates desirable properties in early testing, possibly opening up a multi-billion dollar market. Together with Dr. Hestekin’s graduate student John Moore, and postdoctoral fellow Dr. Soma Shekar Dachavaram, they filed a patent on this new form of incredibly hydrophilic cellulose.

Cellulose is a compound found in plants that keeps the cell walls rigid. It is not digestible, but can be used as dietary fiber and in other applications like cloth and paper. Cellulose is also a byproduct of the forestry industry, historically being used for paper. Research is being done worldwide on finding other applications of cellulose that are of value.

The new material is unique due to its complex nanoscale structure. For reference, a nanometer is somewhere between a strand of DNA and a single atom. Imagine taking one human hair and splitting it lengthwise into 80,000 pieces. The researchers found a way to assemble the cellulose into nanorods and nanoparticles that are less than 10 nanometers in length.

The material also shows promise in hemodialysis applications. During hemodialysis, blood is passed through a filter outside the body like an artificial kidney. Current filters could be improved by allowing better flow-through and less fouling. Testing shows that the cellulose material allows more blood to flow through a specific area in less time, and shorter fouling times.

Private companies have approached the team; they are also exploring it as an edible moisture barrier via dip coating and spray coating methods. The material is biocompatible, biodegradable, and can be produced sustainably. It will likely be a few years before the general public would encounter a product made from this new material, but it is very promising.

This development was supported by the Center for Advanced Surface Engineering, NSF RII Track-1 Award OIA-1457888. For more information on the Center for Advanced Surface Engineering and Arkansas NSF EPSCoR, please visit arepscor.org.

|

Blog post contributed by: Director of Education, Outreach & Diversity, |

Back to the Main Blog

Back to the Main Blog

CATEGORY:

Blogs, Science & Technology, Science and Technology

SHARE THIS:

RELATED BLOGS: